How Fabric Testing for Wear and Shrinkage Works Before Launching a Clothing Collection

When launching a clothing collection, many designers focus on design, fit, and marketing. But there’s one crucial part that separates amateur brands from professionals — fabric testing. Before the first piece hits production, materials go through tests for wear, shrinkage, and durability. These steps determine how the garment will perform in real life, how long it will last, and whether customers will trust your brand again after washing their clothes for the first time.

Understanding Why Fabric Testing Matters

Every fabric tells a story, and not all stories end well. A perfect-looking textile in the store may lose shape, fade, or pill after a few washes. That’s why professional brands test fabrics long before sewing samples. The goal is to predict how the material behaves under real conditions — stretching, washing, friction, and even sunlight.

Fabric testing is quality control before production, not after. Once you approve the wrong fabric and start cutting, mistakes become expensive. Testing ensures your garments maintain fit, texture, and color stability over time.

Designers often discover surprising results. Some fabrics shrink by 5–10% after the first wash. Others twist or lose elasticity because of how the yarns were spun. This knowledge helps you adjust your patterns and washing instructions before sending anything to the factory.

The Main Tests: Shrinkage, Wear, and Color Fastness

When people talk about “fabric testing,” they usually mean a mix of laboratory and practical tests. The most common ones are shrinkage testing, abrasion resistance, and color fastness. Each reveals a different risk hidden in your fabric roll.

In shrinkage testing, small swatches of fabric are washed and dried under controlled conditions. The change in dimensions is measured against the original size. If a cotton fabric shrinks 4% in length and 2% in width, that might be acceptable for casual wear but unacceptable for tailored garments.

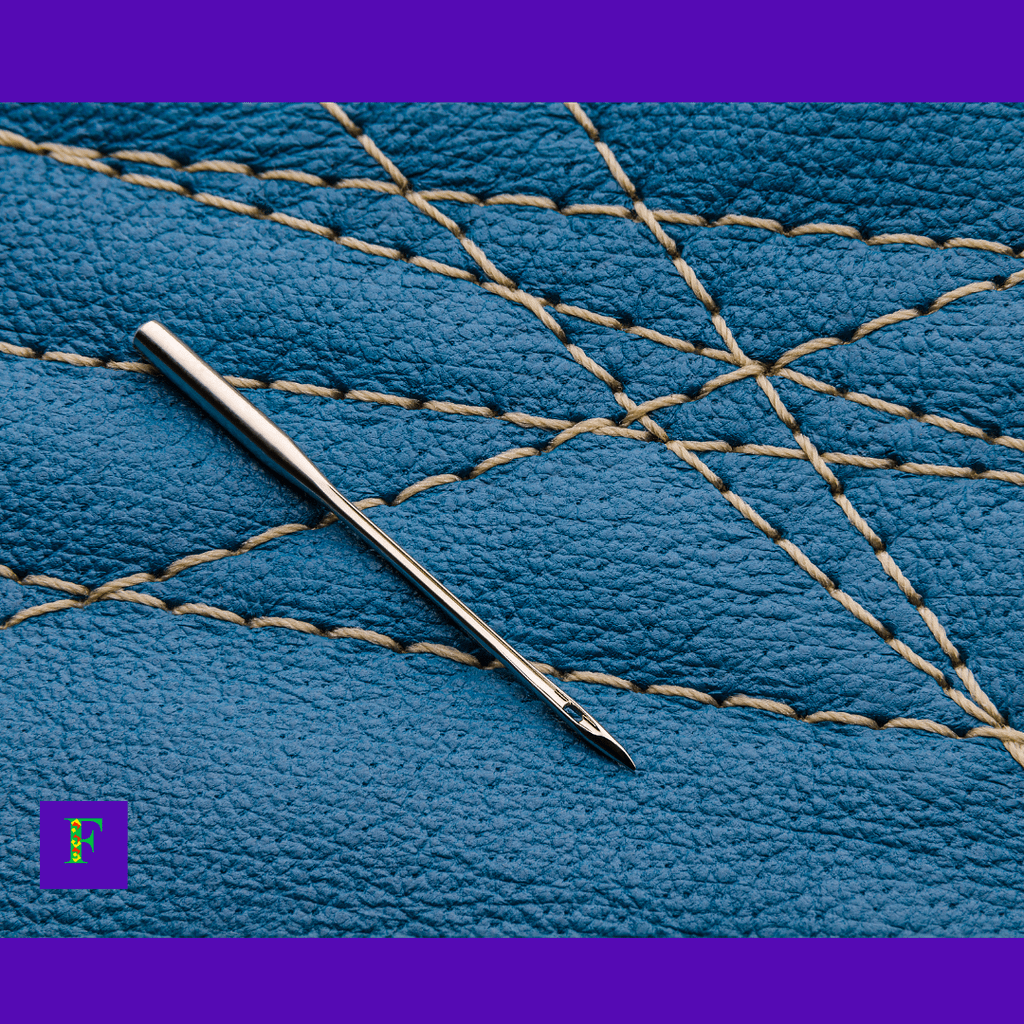

Abrasion testing simulates wear and tear caused by friction. Machines like the Martindale or Wyzenbeek testers rub the fabric repeatedly until the surface breaks down. The number of cycles it withstands defines its durability rating. A sofa fabric might need 40,000 rubs, while a T-shirt can survive with far less.

Color fastness testing checks how dyes react to washing, light, sweat, and rubbing. A fabric that bleeds or fades too quickly can ruin an entire batch of clothing. That’s why most brands set minimum fastness grades before approving any textile.

These tests sound technical, but their purpose is simple — to make sure your clothes still look and feel great after customers actually wear them.

How the Testing Process Happens in Real Life

In reality, few young brands own professional testing machines. Instead, they rely on independent textile labs or factory partners to perform these checks. A typical process begins with the designer or production manager sending fabric swatches (usually 50×50 cm) to the lab. The lab conducts standardized tests following ISO, ASTM, or AATCC methods and issues a detailed report.

However, small brands often perform practical home tests as a first step. They cut a 30×30 cm piece, wash it according to care label instructions, dry it, and measure how much it shrinks. If the shrinkage exceeds 3%, they know it needs pattern adjustment or prewashing.

Prewashing, also known as “sanforization,” is common in denim and cotton production. The fabric is washed or steamed before cutting, reducing future shrinkage. Brands that skip this step risk uneven fits after customers’ first wash.

Beyond washing, professionals test stretch recovery for elastic materials. The fabric is stretched by a fixed percentage, held, then released to see if it returns to its original length. This is vital for activewear or skinny jeans, where shape retention defines product quality.

Testing may also include pilling resistance (small fiber balls forming on the surface), tearing strength, and seam slippage — how easily threads pull apart under tension. Each metric helps refine the fabric choice and construction technique.

Adjusting Design and Production Based on Test Results

Once testing results are in, the real work begins. Numbers alone mean nothing unless you know how to apply them. For example, if shrinkage is 5%, a designer must either adjust the pattern by that percentage or change the washing method.

If abrasion resistance is low, the brand may need to reinforce stress areas or switch to a blended fabric with better fiber strength. Color fastness issues can sometimes be solved by changing the dyeing process or using a finishing treatment.

Large fashion houses run these adjustments like clockwork. For smaller labels, this stage often feels like trial and error, but it’s the only way to create reliable garments. Each round of testing brings you closer to consistent quality and predictable results.

A strong brand reputation starts in the testing room, not on Instagram. When your customers realize your clothes don’t shrink, fade, or fall apart, they start trusting your label — and that’s what builds loyalty in the long run.

Why Testing Is an Investment, Not a Cost

Testing might look like an extra expense, especially for startups watching every dollar. But skipping it often costs more. Imagine producing 300 hoodies that all shrink after washing. The refund requests, bad reviews, and wasted materials will exceed the cost of proper testing tenfold.

Testing protects your reputation and budget. It helps you choose fabrics that match your product’s purpose — whether it’s high-performance sportswear or delicate silk blouses. It also gives you professional credibility when negotiating with manufacturers.

Many experienced designers treat testing reports like a passport for each fabric. They keep records of shrinkage, pilling, and color fastness from previous collections. Over time, this builds a library of trusted suppliers and materials, saving both money and headaches.

Finally, testing aligns with sustainable fashion principles. Producing longer-lasting clothes means fewer returns, less waste, and more satisfied customers. It’s one of the simplest ways to make your brand truly sustainable — through quality that lasts.